High-temperature brazing under shielding gas makes it possible to join different types of steel such as non-ferrous metals, high-alloy materials and hard metal with an absolutely bright finish. Copper, nickel and silver are mainly used as brazing solders.

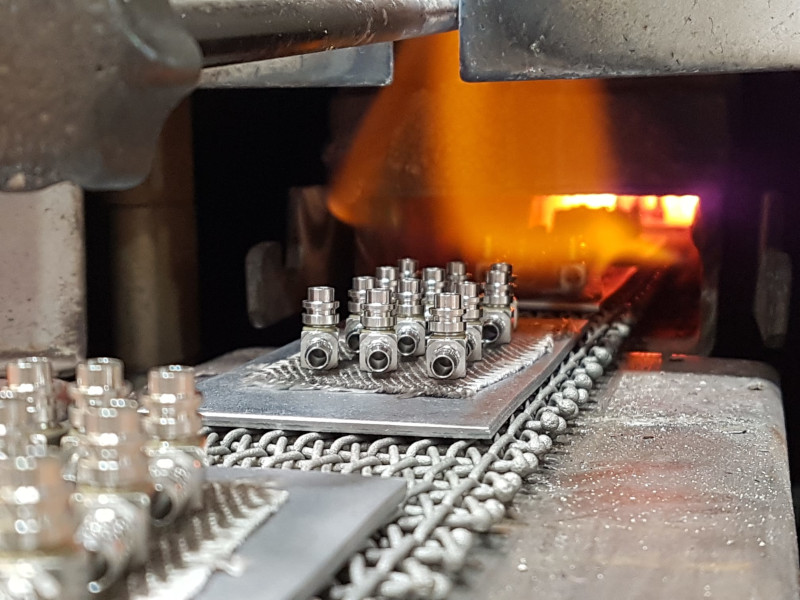

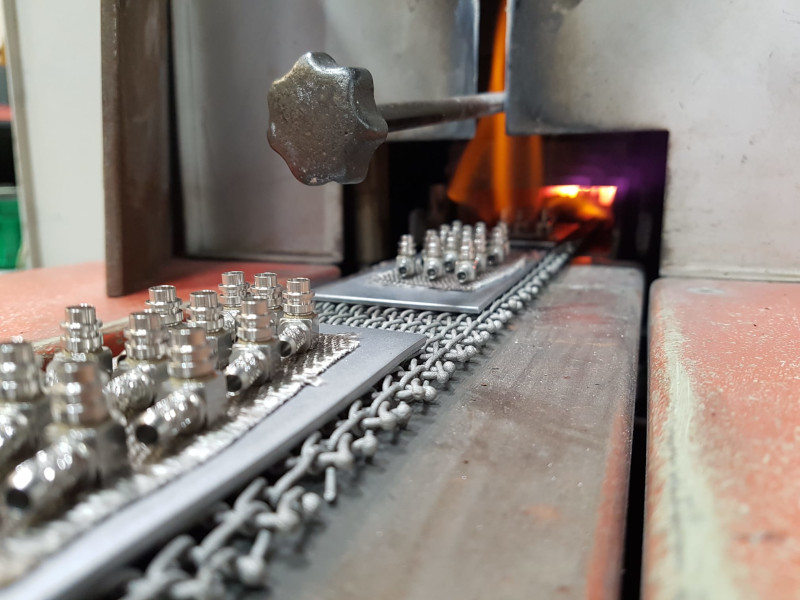

In our continuous furnaces, serial parts are brazed together without the use of flux. Let us convince you.

Grag AG is a specialist in the field of brazing / high-temperature brazing under shielding gas. With various continuous belt furnaces and decades of experience, we can offer you top quality at an optimal price-performance ratio – for both large and small series.

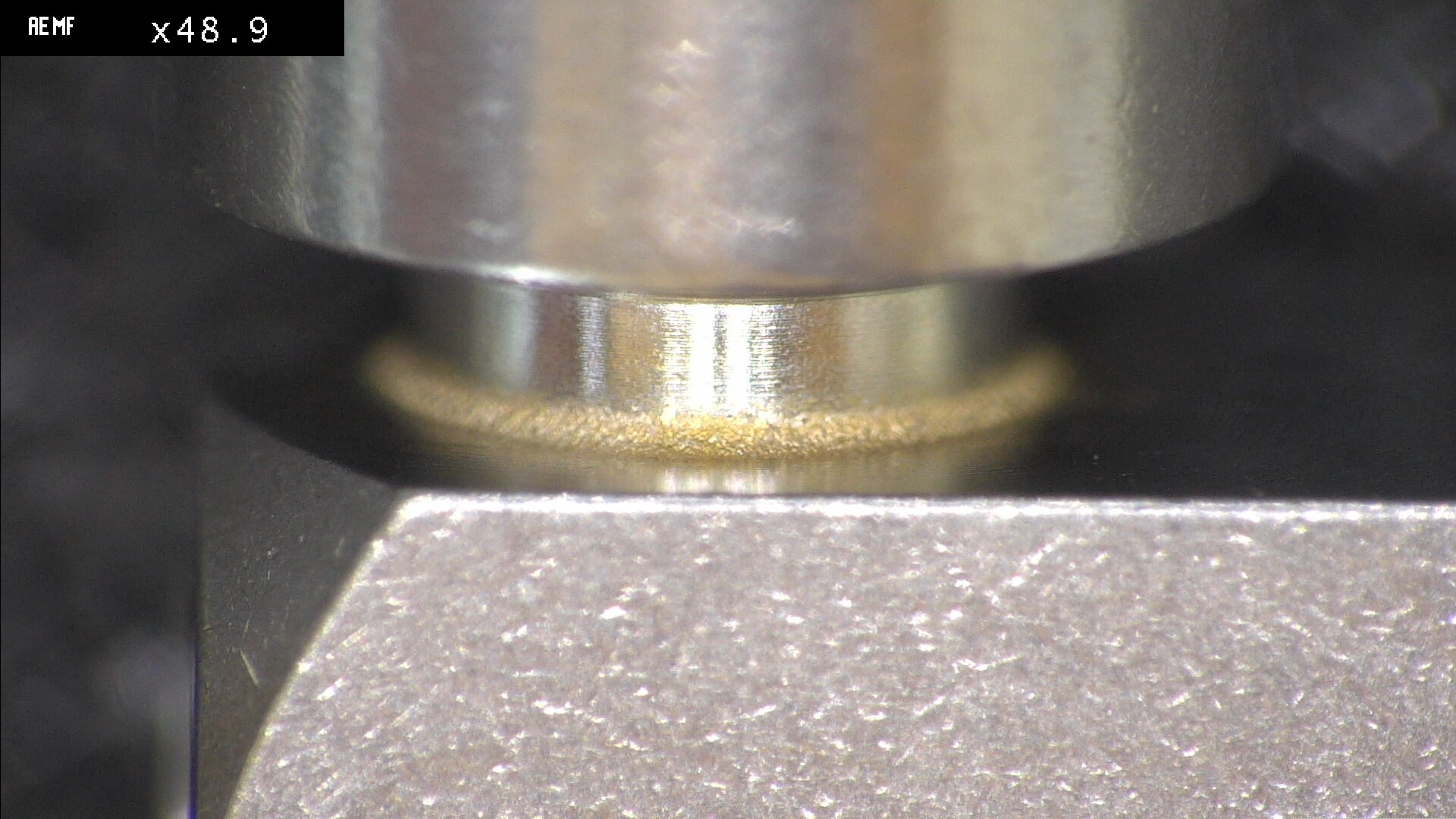

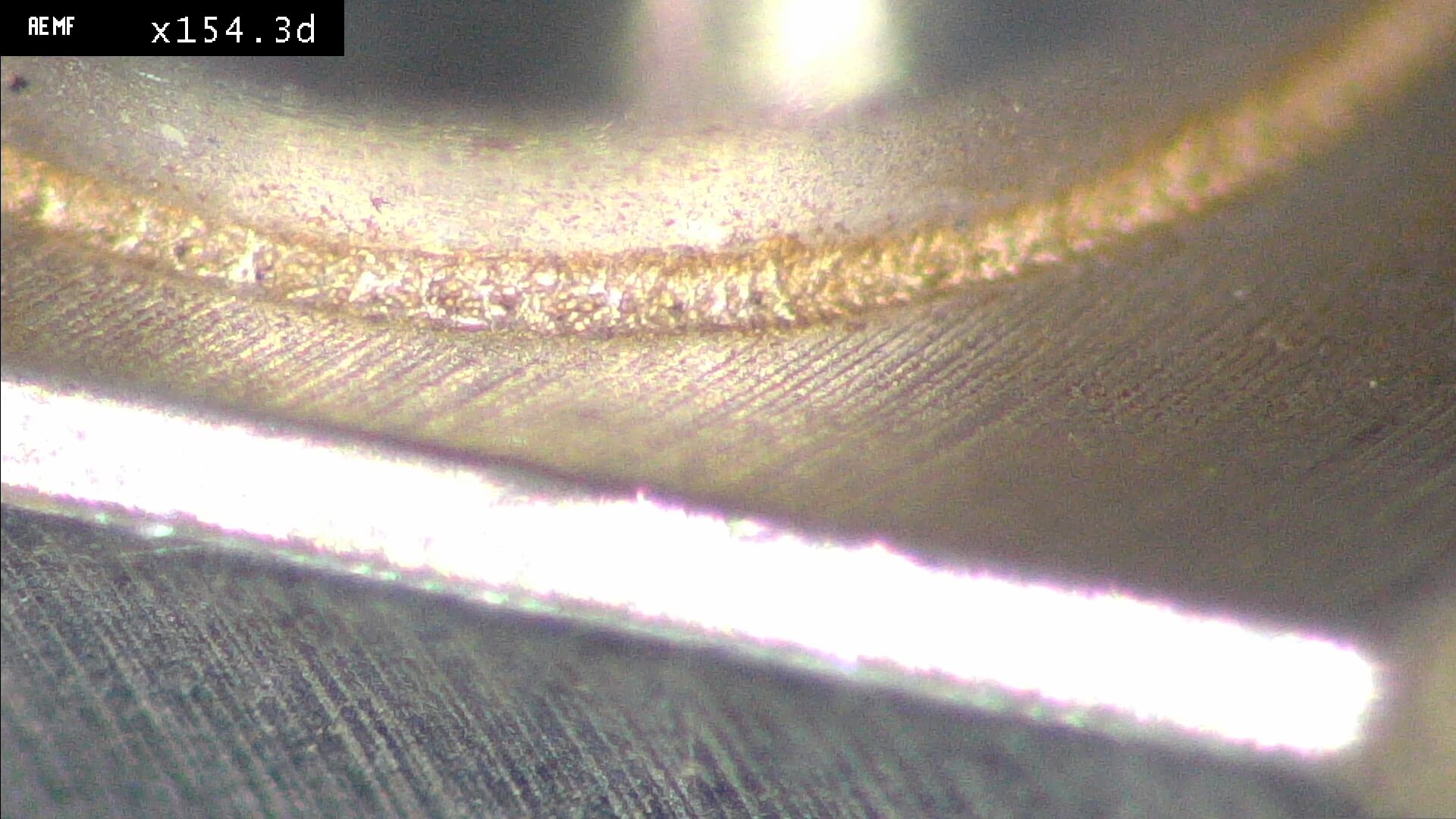

Brazing at temperatures above 450 °C and high-temperature brazing at over 900 °C can also be carried out in the absence of air. This exclusion of air in a shielding gas atmosphere leads to bright, scale-free brazed parts. Among other things, we specialize in the brazing of brass parts.

Thanks to our various continuous belt furnaces, we can use the optimal furnace for specific brazed parts – considering their size or metal.

Traditionally, brass, copper or gunmetal parts are torch or induction brazed. For these types of brazing, flux is required to wet the solder. The parts to be brazed are heated up to 750° C in the air, i.e. exposed to oxygen. This leads to oxidation of the brass part and, as a result, to a black discoloration at the brazing point. In addition, flux residues remain on the brazing part.

Usually, the brazed brass parts receive a galvanic treatment after brazing. The prerequisite for this is an absolutely clean and bright surface. The surfaces can be cleaned mechanically, e.g. by brushing and/or polishing, or also galvanically with various pickling baths. Both cleaning processes are time-consuming and expensive and do not correspond to today’s environmental protection standards. Thanks to shielding gas, brass, copper or gunmetal parts can be brazed together absolutely bright in an environmentally friendly manner. The previous expensive and time-consuming cleaning processes are no longer necessary. This way, the products can be used for their final purpose without post-treatment. Others receive a galvanic surface treatment. Should it be additionally requested, we can offer brass blasting in our facility.

Stainless steels require higher temperatures for the brazing process. We have also been brazing these metals brightly for decades.

GRAG Härterei + Apparatebau AG

Industriestr. 35, Liestal

4402 Frenkendorf

Tel.: +41 61 901 47 40

Fax.: +41 61 901 60 39

© 2021 GRAG Härterei + Apparatebau AG